Following its partnership with Castor, Oqton has introduced Oqton Build Quality software, enhancing Manufacturing OS (MOS) and 3DXpert products, to trace part quality and evaluate build performance.

Oqton Build Quality combines 3DXpert Build Simulation, MOS Build Monitoring, and 3DXpert Build Inspection to oversee the complete manufacturing process and rectify errors in build setup, printing, and materials. Identifying and rectifying anomalies at an early stage guarantees successful builds, from initial inspection to the final part. This enables manufacturers to establish consistent processes for both prototyping and production, resulting in cost-effective, high-quality parts. Oqton is showcasing the capabilities of Build Quality in its Hall 11.1, booth C22 at Formnext 2023.

“Recently, metal additive manufacturing has evolved as a technology for reliable serial production of end-use parts,” said Tomasso Tamarozzi, Product Director, Additive Manufacturing, Inspection & Simulation, Oqton. “However, the industry still had to take very deliberate measures to ensure that production quality was held to very high standards. There was a lack of standardized procedures, disparate hardware components, and multiple software vendors, but not one reliable solution. With the introduction of Build Quality, Oqton is delivering a single actionable, reliable solution that addresses all these aspects. Through collaboration with strategic partners, such as Baker Hughes and our colleagues in 3D Systems, Oqton can provide a reliable printer-agnostic solution built on AI and physics-based simulation. I look forward to the opportunity to continue to expand our portfolio with solutions such as this that deliver unique, critical benefits for manufacturers.”

In other news, Pennsylvania-based service bureau FreeFORM Technologies has selected Oqton’s software, Manufacturing OS, and 3DXpert to enhance its production workflow.

AI-powered quality assurance for additive manufacturing

Oqton Build Quality serves manufacturers using additive manufacturing technologies, including OEMs, service bureaus, engineering teams, and quality assurance professionals. The solution concentrates on critical stages before, during, and after the build to optimize processes and results.

Prior to part production, the aim is to predict print quality and eliminate design issues before initiating the first print. During this phase, 3DXpert Build Simulation plays a crucial role in predicting printability problems and preventing part overheating. It achieves this by suggesting minor design revisions and providing recommendations for part orientation and support strategies as part of the build preparation process.

The software employs parallelization and voxel technology to streamline simulation, minimizing iteration time and material wastage. This ensures top-quality results on the first attempt. During the build, MOS Build Monitoring, created in partnership with Baker Hughes, uses AI models to detect potential defects in real-time, allowing users to track each part’s every layer. This functionality boosts process reliability, maintains quality, and prevents financial losses from part failures.

After the build, the quality inspection process ensures that the parts meet design specifications. 3DXpert Build Inspection helps users analyze the final parts compared to the initial expectations. Any anomalies trigger corrective actions to enhance future part quality and maximize production output.

FreeFORM Technologies boosts production efficiency with Oqton’s Manufacturing OS

FreeFORM Technologies produces 500,000+ parts annually for diverse industries. By incorporating Oqton’s Manufacturing OS into its operations, the company will automate repetitive tasks, improve the estimating process, and enhance part traceability. The integration of Oqton’s 3DXpert software will streamline the entire additive manufacturing workflow. With Oqton’s support, this comprehensive solution aims to boost production efficiency, positioning FreeFORM Technologies for sustained growth and competitiveness, particularly in highly regulated sectors.

Oqton’s software is known for its seamless integration with existing workflows, breaking down data silos between business systems like CRM, ERP, QMS, and PLM, says the company. The Manufacturing OS enables configurable production environments for real-time monitoring, enhancing process visibility, historical record-keeping, and utilization improvement through analysis and optimization, benefiting manufacturers seeking efficient and integrated solutions.

Oqton’s integration of 3DXpert with Manufacturing OS automates build preparation, utilizing AI to replicate expert preferences and past setups, encompassing tasks like part orientation, support generation, nesting, slicing, and build process simulation and compensation. This streamlined workflow from design to printing enhances production efficiency, saving time and resources.

“We awarded this contract to Oqton because the team has extensive expertise in additive manufacturing processes, and Oqton’s Manufacturing OS platform was built from the ground up specifically for AM,” said Chris Aiello, VP of business development, FreeFORM Technologies. “This enables robust performance and ease of use even with the most complex workflows in which revision control is critical. We will achieve significantly more accurate forecasts for the actual cost of our production process compared to estimated costs. Oqton found the balance between simplicity and complexity.”

Read all the 3D Printing Industry coverage from Formnext 2023.

Voting has now started for the 3D Printing Industry Awards 2023. Cast your vote now!

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

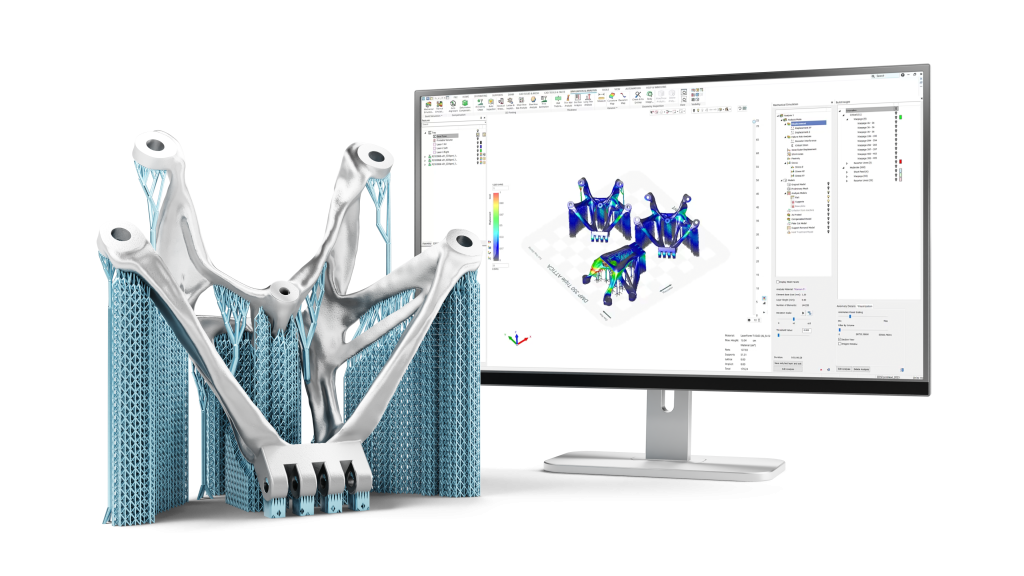

Featured image shows 3D printed 3DS bracket being inspected on a monitor using Oqton’s 3DXpert software. Photo via Oqton.