Researchers from the University of Leeds, University of Greenwich, and medical device testing firm Cormica Limited have published a new review paper on powder bed fusion (PBF) 3D printing. Published in Particuology, it evaluates how powder spreading in PBF impacts final part characteristics.

The new paper, titled ‘Spreadability of powders for additive manufacturing: A critical review of characterisation methods,’ seeks to fill a gap in the current literature. It highlights progress in understanding powder spreading dynamics. The impact of powder properties, environmental conditions, and powder spreading systems on the quality of 3D printed parts are also emphasized.

Additionally, the researchers outline the development of testing tools to assess powder spreadability. They examine the challenge of identifying appropriate quantitative metrics for evaluating powder spreadability and identify recent advances in standardized methods.

Through this study, the team sought to create a “coherent and comprehensive understanding of the existing knowledge.” They hope this will improve PBF 3D printing and enhance quality control.

Ultimately, the authors advocate for a holistic approach to characterizing powder spreadability in PBF 3D printing. Despite “substantial research efforts” to measure and define spreadability using traditional flowability evaluations, they highlight a “substantial mismatch” between standardized measurements and powder behavior.

How powder spreading impacts 3D printed part characteristics

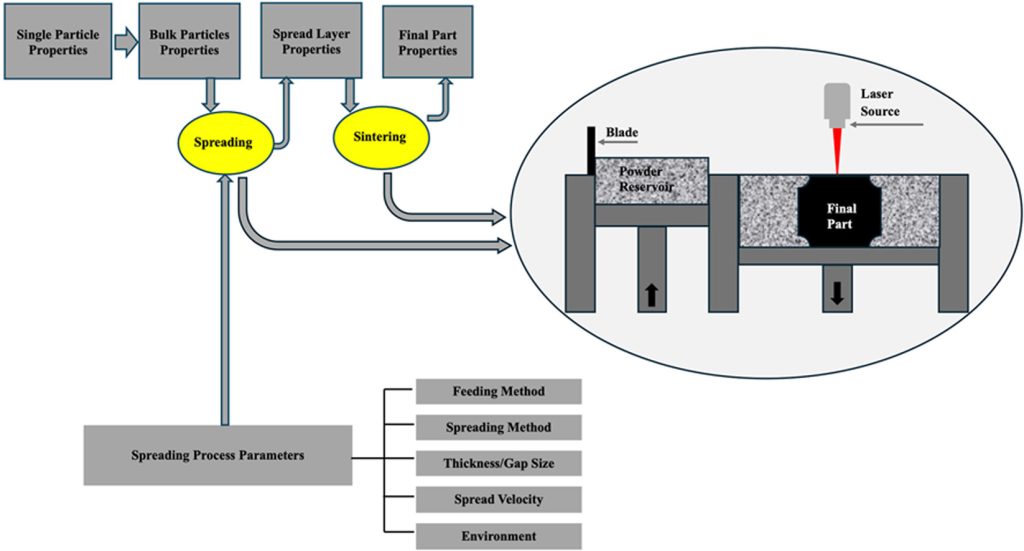

During PBF 3D printing, thin layers of powder are spread over the build plate by a blade or roller. A heat source, such as a laser or electron beam, melts or sinters pre-defined paths in the powder. This process is repeated layer-by-layer until the desired part has been fabricated.

Powder must be spread evenly and consistently during 3D printing to ensure repeatable production of high-quality parts. Spreadability, the ease at which the powder is spread along the powder bed, strongly influences this.

For instance, greater powder packing density improves mechanical properties in the final part. Powder characteristics such as size, size distribution, morphology, particle structure, surface properties and powder flow behavior also influence the processability of 3D printing powders, impacting part quality.

The researchers argue there is currently limited understanding of powder behaviour during the spreading process. While attempts have been made to correlate standardized measurements with spreadability, these have reportedly fallen short. This is due to discrepancies between real and simulated powder spreading conditions.

Throughout the paper, the researchers identify significant factors impacting powder performance in PBF 3D printing, and their impact on final part characteristics. These include particle size, particle morphology, porosity, packing behavior, and powder flow.

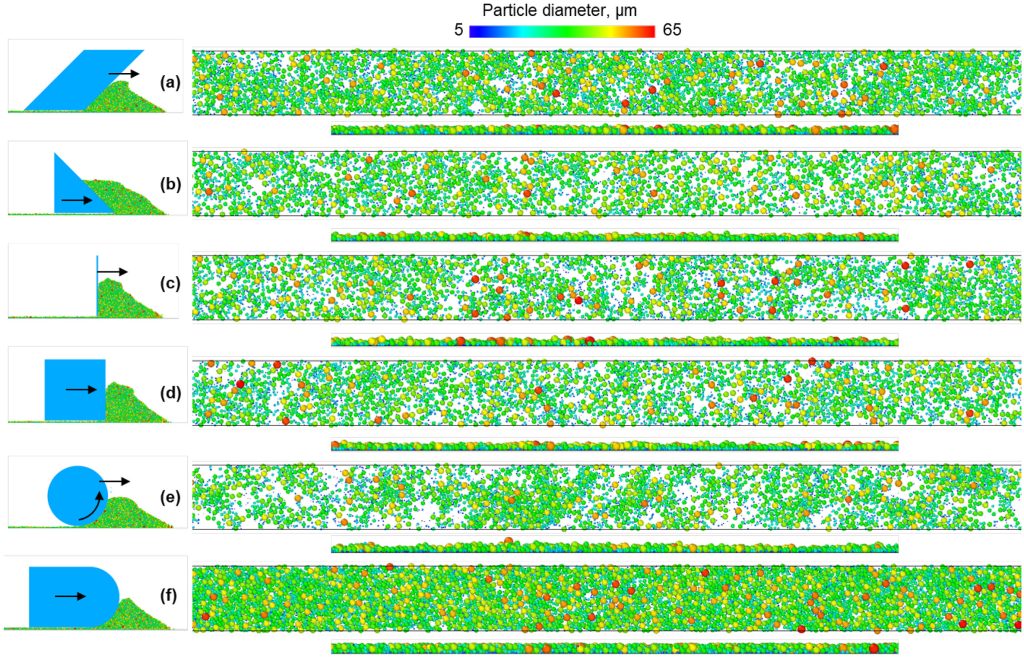

They also highlight the impact of spreading conditions. The gap size between the spreader and build plate, spreader velocity, spreader type and material, and environmental conditions impact PBF 3D printing performance.

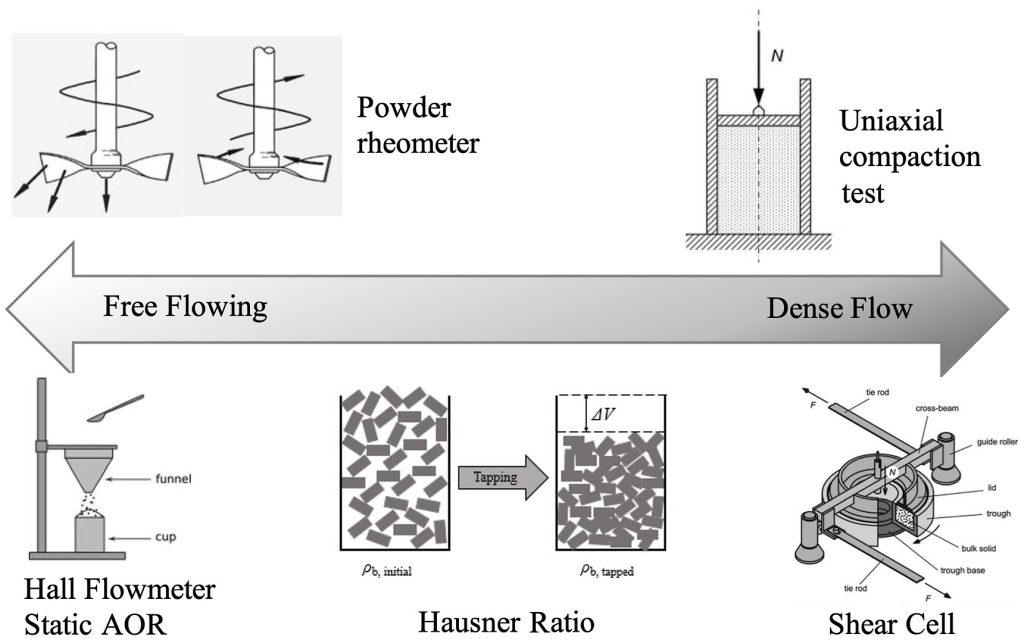

An overview of flow measurement techniques is also provided. This reportedly poses a major challenge as most techniques such as shear cell, Hausner ratio, angle of repose and powder rheometer measure indices rather than powder properties.

How to improve PBF 3D printing

The authors highlight that there is no universally accepted definition of spreadability or standard spreadability metrics. They call this a “notable gap” in the research, pointing to the lack of powder characterization techniques to predict material behavior within the powder feedstock.

The paper also points to a knowledge gap between the impact of powder characteristics and 3D printing process parameters on powder spreading and final part quality. It argues that existing research often isolates these aspects, ignoring the complex interplay necessary for optimal spreadability and process optimization.

The review suggests that individual powder characteristics may be insufficient to provide measures of powder spreadability. It argues that a single characterization method cannot fully represent the powder behavior under spreading conditions. As such, the researchers believe combining different methods and correlating analysis is crucial to developing a greater understanding of powder spreading dynamics.

In-situ monitoring for PBF 3D printing

In the review, the researchers argue that in-situ monitoring software can improve process control and repeatability. Using these tools, users can modify printing settings in response to live spreadability data. This can reduce the potential for failed 3D prints, enable quick iterations and facilitate design optimization.

Last month, Chicago-based 3D printing quality assurance software developer Phase3D launched Fringe Research, a new in-situ monitoring software for laser powder bed fusion (LPBF) 3D printing.

According to Phase3D, Fringe Research is the first software to have measured anomalies during LPBF and correlate these to defects in the final part, such as porosity. Developed in collaboration with the United States Air Force (USAF) and NASA, the software has also been used to validate two materials on different PBF 3D printers.

Consequently, the company calls Fringe Research a “significant leap forward” for ensuring quality and reliability in additive manufacturing. This is a key challenge for aerospace applications, with porosity often causing metal parts to be rejected by the USAF and NASA.

Similarly, Californian metal 3D printer manufacturer Velo3D’s offers its Assure Quality Assurance and Control System. This software monitors the 3D printing process on its laser powder bed fusion (LPBF) Sapphire 3D printers. The platform offers defect detection through its live, multi-sensor, physics-based detection algorithms.

Register now for AMAA 2024 to hear insights from industry experts on additive manufacturing in aerospace, space, and defense.

Want to help select the winners of the 2024 3D Printing Industry Awards? Join the Expert Committee today.

What does the future of 3D printing hold?

What near-term 3D printing trends have been highlighted by industry experts?

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news.

You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Featured image shows top and side profiles of powder spread layers with different spreader geometries. Image via Particuology.